As media architecture becomes an increasingly popular vehicle for the integration of digital technologies into the built environment, a combination of techniques becomes necessary to overcome challenges regarding prototyping form, content and scale. P+ is an open-sourced test fit generative platform for the design of 3D media façades leveraging on recent practices observed in the field of architecture. It consists of a set of modular light cell components that can be assembled into a larger structure; a physical, 3D printing based prototyping kit; and a software tool for generation, testing and live running of façades fulfilling pre-defined contextual constraints.

Modular Light Cell

To build complex 3D media façades on an urban scale, we developed a modular light cell in the shape of a cross measuring 35x35x10 cm. The cell’s outer shell consists of two halves (front and back) made of polyethylene plastic using rotational molding techniques. The front side, with the LEDs facing up, is made of translucent material to create a smooth diffusion, whereas the backside is made of white opaque material. Each cell houses 4 high-power RGB LEDs (108 lumens each) that can be controlled individually via a digital multiplex (DMX) controller.

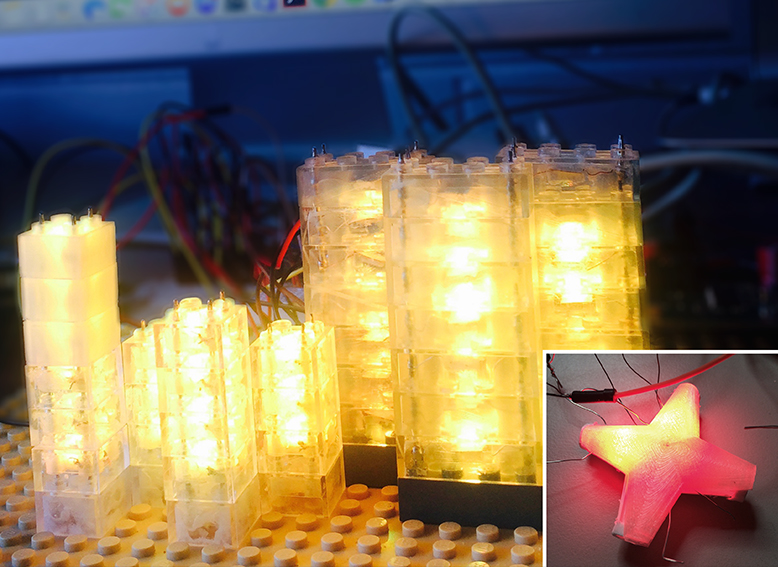

Physical Prototyping Kit

For early prototyping iterations, we adapted the physical prototyping tool LightBricks running content explorations on a small-scale model. LightBricks consists of transparent LEGO-bricks, housing a WS2812B RGB-LED. Stacking ‘pixels’ on top of each other, the tool can be adapted to various structures. To power the LEDs and transfer data, connectors are inserted into the knobs of the bricks. To control LightBricks with our software tool, we connected them to a WS2812B-contoller supporting the art-net protocol, which allows us to simply exchange the miniature model with the actual light cells at a later stage. Furtermore, we took the development of LightBricks forward by using 3D printing to produce a unit in the cross-shaped pixel design of our modular light cell housing 4 individual controllable LEDs. The 3D-printed version follows a press-fit design which allows to “wire” the contacts of the SMD-LEDs without soldering. To simulate the diffusion of our actual modular light cells, we 3D printed the front side in transparent and the backside in white polylactide (PLA) filament.

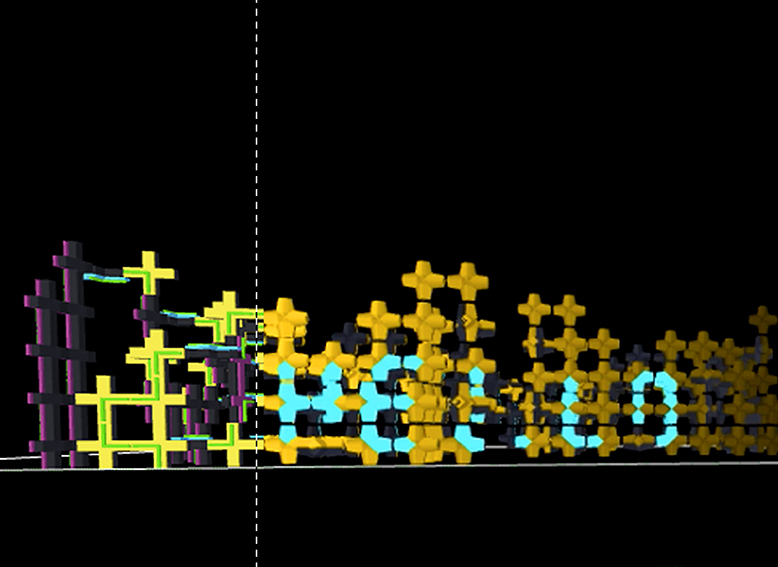

Software Design Tool

We developed a design software tool in Processing for generation, simulation and execution of design solutions for 3D media architecture structures using our cross-shaped light cell. The tool has three basic features: (1) individual cell rendering; (2) 3D media façade generation; (3) exporting of structure layout as blueprint for construction; and (4) execution of visual effects, both as simulation on the digital structure and live running on the physical prototyping kit or final 3D media façade.